Overview: Bushings are essential components widely used in industries such as automotive and oil & gas extraction. They help reduce friction, extend the lifespan of machinery, and improve operational efficiency. Under high-speed and heavy-load conditions, bushings effectively minimize metal-to-metal friction, reducing wear and tear, which in turn extends the lifespan of equipment and lowers maintenance costs.

Applications:

- Automotive Industry: In automotive engines, transmissions, and other key components, bushings play a crucial role. Thanks to their wear-resistant and corrosion-resistant properties, bushings ensure smooth and efficient operation of mechanical systems.

- Oil & Gas Extraction: Bushings are essential in oil and gas exploration and drilling equipment. These components are exposed to high loads, extreme temperatures, and harsh corrosive environments, requiring reliable and long-lasting performance.

- Other Applications: Bushings are used in a variety of heavy machinery, mining equipment, aerospace, and more, designed to perform reliably under high-pressure, high-temperature, and corrosive conditions.

Alloy Advantages: We use CuNi7.5Sn6/CuNi9Sn6(C72700)/CuNi15Sn8(C72900) alloy as the primary material for our bushings, which consists of copper, nickel, tin, and other elements. This material offers several benefits:

- Excellent Wear Resistance: The alloys boast high hardness and wear resistance, effectively reducing friction between mechanical parts.

- Outstanding Corrosion Resistance: This alloy offers excellent resistance to various acids, alkalis, and seawater corrosion.

- Great Fatigue Resistance: The material can maintain stable performance under repetitive loads and impacts, extending its lifespan.

- Good Machinability:CuNi7.5Sn6/CuNi9Sn6(C72700)/CuNi15Sn8(C72900) is easy to machine, making it suitable for various manufacturing processes.

Manufacturing Process: We utilize advanced manufacturing techniques to ensure precision and quality in every bushing:

- Precision Casting: We use advanced casting processes to ensure uniformity and strength in the material.

- CNC Machining: The bushings are precisely machined with CNC equipment to ensure dimensional accuracy and surface smoothness.

- Heat Treatment: Each bushing undergoes a controlled heat treatment process to enhance hardness and fatigue resistance.

- Surface Treatment: We offer various surface treatment options, such as nickel plating and tin plating, to further improve corrosion resistance and surface quality.

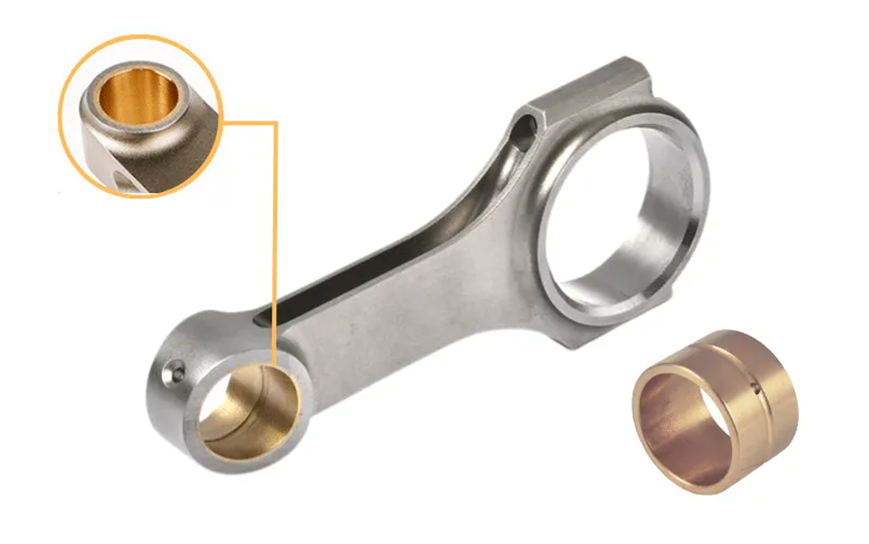

Other services: In addition to bushing parts, we can supply raw material—round bars, and our company also offers manufacturing services for connecting rods. As one of the engine’s core components, the connecting rod plays an important role in linking and transmitting forces. We use the same high-quality materials and precision machining processes as for our bushings to ensure the connecting rods’ stability and reliability under high-strength, high-temperature, and high-pressure conditions.