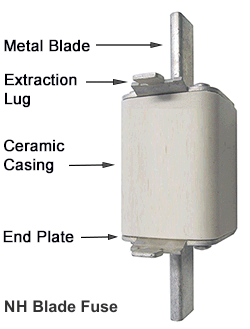

The low-voltage fuse is one of the most commonly used over‑current protection devices in power systems and electronic equipment, and is mainly applied in circuits with a rated voltage. It protects both equipment and personnel by “sacrificing” itself—melting its internal element—to interrupt the circuit whenever an overload or short‑circuit occurs.

Common types include

- NH fuses (knife‑switch fuse type)

- Current‑limiting fuses (small cylindrical type for electronic equipment)

- Plug‑in/blade fuses (common in automotive and electromechanical applications)

- Power fuses (compact design for PCB use)

Selection of Fuse Element Materials

- Low Voltage: Zinc Alloy Z41321( KINMACHI No.:KZ513)、CuSn8、CuZn30

Application: Battery pack in power tools, consumer electronics devices and DC application - High Voltage: Cu-OF、CuZr

Application: ESS、Battery Pack - Dimensions and alloy composition determine the fusing characteristics (time–current curve)

Chemical composition(%)

|

|

min |

max |

|

Cu |

0.5 |

0.7 |

|

Ti |

0.12 |

0.18 |

|

Fe |

/ |

0.1 |

|

Zn |

Rest |

|

Zinc Alloy Application Guidelines

- Electrical Conductivity: 26%-28%IACS

- Tensile Strength: 150-220MPa

- Voltage: 60VDC

- Current: 30A-100A

- Soldering type: Wave Soldering

- Soldering Temperature: 230℃-260℃ (depending on the type of the solder alloy)

- Function: These fuses are used for current interruption only, not for short circuit protection.

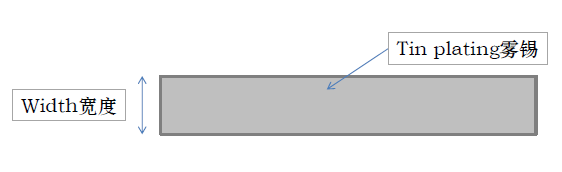

Typical Guideline

- Zinc Alloy + Tin plating:

- Zinc Alloy + Ag plating

Rationale for Material Selection

- Low solidus/liquidus temperatures: Enables the fuse to melt quickly and predictably within a controlled temperature range, ensuring rapid circuit interruption under overload and protecting downstream equipment and wiring.

- Low latent heat of fusion: Requires less total energy (I²t) to melt under rated overload current, enhancing fuse sensitivity.

- High electrical and thermal conductivity: Minimizes voltage drop and heat generation during normal operation, and promotes rapid heat dissipation during the early stages of short‑circuits or overloads, preventing unstable premature melting or damage from local hotspots.

- Excellent formability: Highly amenable to cold working, allowing precision stamping and shearing with minimal scrap and excellent dimensional stability.

- Good corrosion resistance

Low material cost: Zinc alloy costs only about 10–20 % of an equivalent volume of copper and offers stable, year‑round availability from abundant sources.

Because Z41321 strikes an exceptional balance among melting temperature, electrical and thermal conductivity, stampability, alloy strengthening, and cost, it is the material of choice for low‑voltage blade and plug‑in fuses. Its predictable melting behavior, high reliability, and economic advantages are key to designing and manufacturing high‑performance low‑voltage fuses.